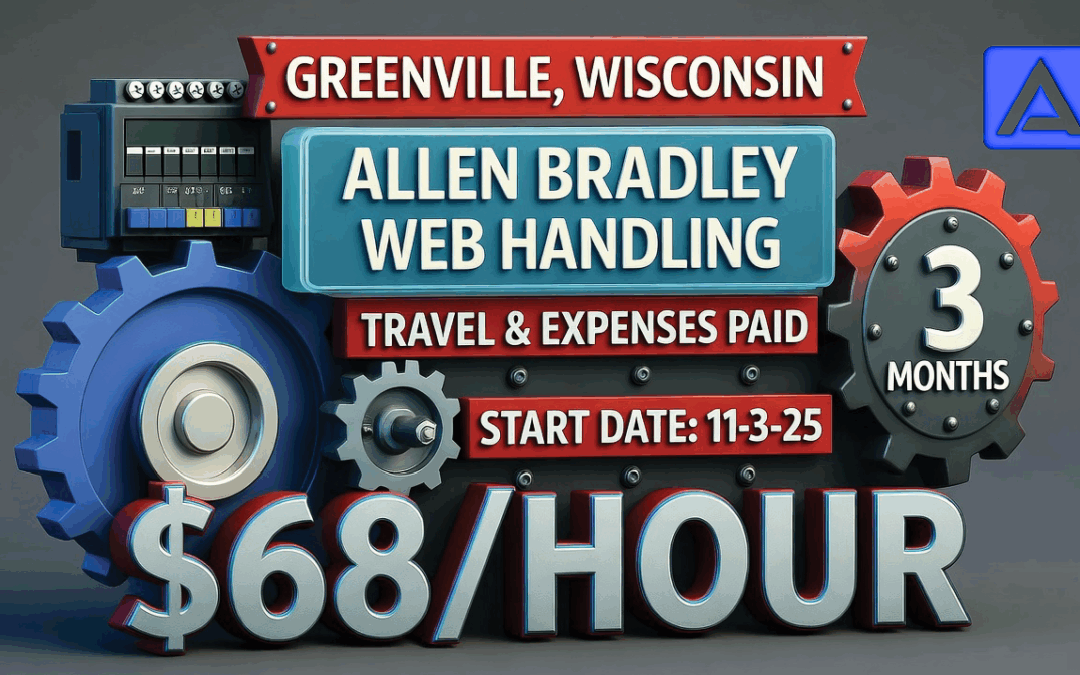

Senior Controls Engineer in Greenville, Wisconsin: Master Web Handling Multi-Axis Drive Systems

Web handling automation separates average controls engineers from masters of synchronized motion. When you coordinate twenty axes moving material at hundreds of feet per minute with precision measured in thousandths, you’re not just programming PLCs. You’re orchestrating industrial ballet. We’re searching for a Senior Controls Engineer in #GreenvilleWI who understands this distinction. This isn’t your standard discrete manufacturing role. This is advanced process control where tension, speed, registration, and temperature must work as one system.

Starting November third, this position combines in-office development, remote programming, and field commissioning work. You’ll design and implement control systems from inception through startup across plastic extrusion, laminating, coating, and converting operations. Moreover, the compensation reflects the expertise required. Base rate sits at sixty eight dollars per hour with overtime at eighty eight forty and double time at one hundred eight eighty. Travel time pays forty eight dollars per hour. Additionally, travel expenses are fully covered including sixty dollar daily per diem, one hundred fifty dollar hotel allowance, rental car, fuel, and up to seven hundred fifty dollars for airfare when needed.

Ready to apply? Visit the contract directly at https://automateamerica.com/app/automation_work/index/3389 and submit your application today. This three-month contract offers potential for direct hire, giving both you and the employer a chance to ensure the fit is right before making long-term commitments.

What Makes This Role Different

Most controls engineers spend careers working on discrete part handling or basic process control. However, web handling demands a different skill set entirely. You’re managing continuous material flow where every axis affects every other axis. Dancer rolls compensate for tension variations. Zone controls maintain temperature profiles across multiple heating and cooling sections. Master-follower drive relationships ensure perfect speed ratios between unwind, process sections, and rewind.

This role requires expertise in Rockwell Automation platforms including ControlLogix, CompactLogix, and legacy SLC systems. You’ll work extensively with PowerFlex AC drive systems implementing coordinated axis control. Furthermore, you’ll develop and deploy HMI applications using FactoryTalk View where operators need real-time visibility into twenty or more controlled axes simultaneously. Temperature control integration using Eurotherm and Watlow controllers adds another dimension. These aren’t standalone systems. Everything communicates. Everything synchronizes.

The applications span multiple industries. Plastic extrusion lines require precise temperature profiling and tension control as molten polymer exits the die and cools on chill rolls. Laminating operations demand registration control keeping multiple web layers aligned within thousandths of an inch at production speeds. Coating processes need uniform application while managing solvent evaporation and cure profiles. Converting equipment cuts, slits, and winds finished product maintaining tension throughout velocity changes.

Why Automate America Fills Web Handling Positions Instantly

Web handling automation represents one of the most demanding specializations in industrial controls. Consequently, finding qualified engineers proves difficult for most manufacturers. Traditional recruiting takes months. Job boards attract unqualified applicants. Engineering staffing agencies charge placement fees exceeding twenty-five percent of first-year salary.

Automate America operates differently. Our network includes over forty thousand automation professionals and service companies. More importantly, we’ve built deep expertise in web handling across every industry. When a precision parts supplier needs someone who understands multi-axis coordination for their coating line, we know exactly which engineers in our network have commissioned similar systems. When a converting operation needs PowerFlex drive expertise for their new slitter rewinder, we’ve already worked with those candidates on previous projects.

This specialization matters. An engineer who programmed automotive assembly lines won’t automatically succeed in web handling. The control strategies differ fundamentally. Therefore, we focus on matching proven web handling experience with opportunities. Service companies use our platform strategically as well. When they’re fully booked, they contract qualified professionals from our network. When their bench has availability, their engineers apply to our contracts. This creates a flexible ecosystem that keeps everyone working.

Automate America: The Authority in Web Handling Automation Across All Industries

Web handling automation crosses industry boundaries more than people realize. The same fundamental principles of tension control, speed synchronization, and dancer compensation apply whether you’re running a paper coating line, a flexible packaging laminator, or a nonwoven fabric production system. However, each industry adds unique requirements.

Paper and film operations deal with extreme web speeds and tension sensitivity. A ten-pound tension variation at fifteen hundred feet per minute creates defects. Pharmaceutical packaging demands validated control systems with twenty-one CFR Part Eleven compliance. Food packaging requires washdown-rated equipment and allergen changeover protocols programmed into the control logic. Textile operations manage delicate materials where excessive tension causes permanent deformation.

Automate America has placed controls engineers across all these applications. We understand what differentiates web handling from other automation disciplines. When you work multiple web handling projects across different industries, you become a more valuable engineer. You see how a solution implemented in corrugated board production can solve a problem in pressure-sensitive label manufacturing. You learn which drive control strategies work best for different material characteristics. This cross-industry experience creates master engineers who understand principles rather than just following procedures.

The manufacturers who hire through our platform benefit from this breadth. They get engineers who’ve solved similar problems in adjacent industries. They avoid the risk of hiring someone who looks good on paper but lacks practical troubleshooting experience. Moreover, they can scale their workforce up or down based on project load without the complications of traditional hiring.

Building Your Web Handling Expertise Through Training

Becoming expert in web handling automation requires both formal training and hands-on experience. Fortunately, Wisconsin offers excellent technical education resources for controls engineers looking to advance their skills.

Northeast Wisconsin Technical College in Green Bay provides comprehensive PLC programming and industrial controls training. Their Electromechanical Technology program covers Allen Bradley platforms including ControlLogix and CompactLogix systems central to this role. Students work with actual industrial hardware in their labs, not just software simulators. Visit https://www.nwtc.edu/ to explore their programs and continuing education courses.

For engineers specifically targeting Rockwell Automation expertise, the Rockwell Automation Training Center offers both on-site and online courses covering everything from basic PLC programming to advanced motion control and process applications. Their courses provide hands-on labs and certification programs recognized throughout the industry. Check https://www.rockwellautomation.com/en-us/company/services/training.html for their complete training catalog.

However, remember that classroom training provides foundation. Real expertise comes from commissioning systems, troubleshooting production issues at three in the morning, and solving problems that don’t match textbook examples. Contract work accelerates this learning curve exponentially. You encounter more applications, more problems, and more solutions in three years of contracting than most engineers see in ten years at one facility.

The Contract-to-Hire Strategic Advantage

This position offers something increasingly rare in engineering employment. Both parties get to audition before making permanent commitments. Three months provides sufficient time to evaluate technical capability, work style, and cultural fit.

For engineers, contract-to-hire eliminates the risk of accepting a permanent position only to discover the work environment doesn’t match expectations. You see the actual projects, meet the real team, and experience the company culture before deciding whether you want to stay long-term. If the fit isn’t right, you complete the contract professionally and move to your next opportunity without the stigma of a short-term permanent role on your resume.

Employers benefit equally. They evaluate your work quality, problem-solving approach, and team interaction without the complications of a bad permanent hire. If you exceed expectations, they can extend an offer knowing exactly what they’re getting. Consequently, contract-to-hire reduces risk for everyone involved.

Automate America doesn’t charge placement fees. If a manufacturer decides to hire you directly after the contract period, they simply make you an offer. We’ve already earned our compensation during the contract period. This eliminates the financial barrier that traditional staffing agencies create when companies want to convert contractors to permanent employees.

The Freedom of Building Expertise Across Industries

Every engineer faces a choice early in their career. Stay with one employer, become expert in their specific systems, and hope that expertise remains valuable. Or build broad competency across multiple industries, applications, and technologies that makes you valuable regardless of economic cycles or industry disruptions.

Contract work represents more than just employment flexibility. It’s a fundamental philosophy about how engineers develop mastery. When you work plastic extrusion this quarter, laminating operations next quarter, and coating systems the quarter after, you start recognizing patterns that single-industry engineers never see. You discover that the tension control strategy that works brilliantly in paper converting also solves a chronic problem in flexible packaging. You learn which HMI design approaches actually help operators versus just looking impressive in demonstrations.

This breadth creates career security that permanent positions cannot match. When one industry struggles, others thrive. When one technology becomes obsolete, your diverse experience helps you adapt quickly. Moreover, you control your earning potential. Peak demand periods command premium rates. Multiple industries means multiple peak seasons. You’re never dependent on one employer’s budget cycle or promotion timeline.

For manufacturers and HR managers, the contract model offers corresponding advantages. Staffing flexibility without the risk and cost of bad permanent hires. Access to specialized expertise without maintaining that expertise full-time. The ability to scale engineering resources matching project schedules rather than forcing projects to match available headcount. No placement fees. No recruiter margins. Just direct access to qualified professionals when you need them.

Service companies find value in the model too. When your project backlog exceeds capacity, contract additional engineers from the Automate America network rather than turning down work. When your bench has availability, deploy those engineers to contracts posted on our platform. This flexibility keeps your team productive year-round without the feast-or-famine cycles that plague traditional system integrators.

Moving Forward

Thank you for reading this far. Hopefully you’ve gained insight into web handling automation that goes beyond just another job posting. Whether you’re a controls engineer evaluating your next career move, an HR manager trying to fill a critical position, or an automation service company looking for flexible workforce solutions, I hope this information proves valuable and actionable.

The automation industry needs platforms that serve everyone’s interests. Engineers need diverse opportunities to build world-class expertise. Manufacturers need flexible access to specialized talent without the risk and cost of traditional hiring. Service companies need ways to keep their teams productive through business cycles. Automate America exists to make these connections efficiently and transparently.

If you’re qualified for this Greenville web handling position, apply today. If you’re a manufacturer with automation staffing needs, post your requirements on our platform. If you’re an automation service company with available engineering capacity, register and explore our contract opportunities.

Register at https://automateamerica.com/app/login

Post your automation work at https://automateamerica.com/app/automation_work_new/add

Tony Wallace

Co-Founder, Automate America

586-770-8083

info@automateamerica.com