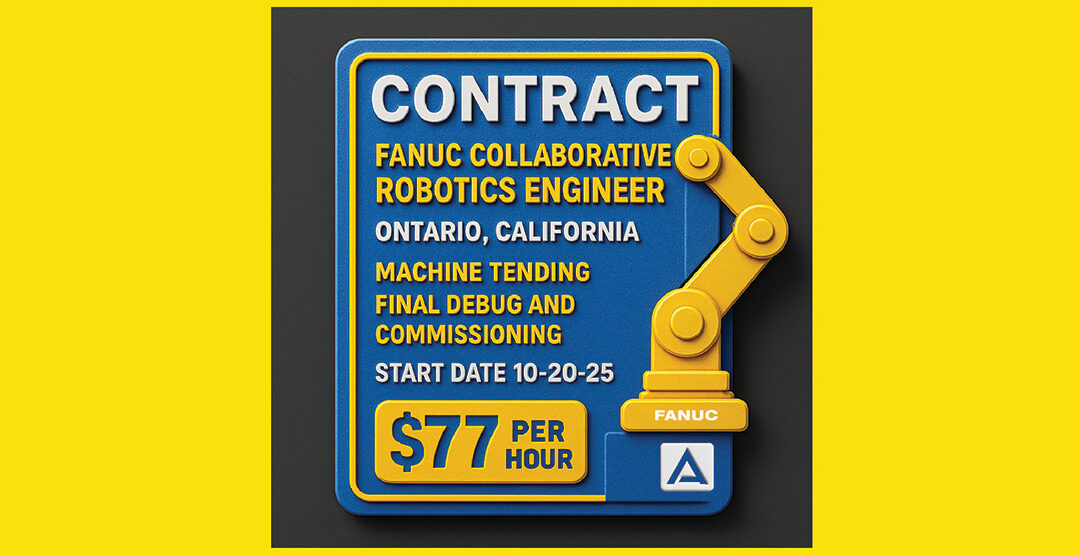

Fanuc CRX Collaborative Robot Programmer Needed for Aerospace CNC Machine Tending in Ontario, California

The precision aerospace industry doesn’t sleep, and neither does the demand for skilled robot programmers who can commission collaborative automation systems. Right now, a critical Fanuc CRX-20iA/L collaborative robot system sits in Ontario, California, waiting for final debug and commissioning before it begins handling precision aerospace components for military and defense applications. This is exactly the kind of project that separates competent programmers from exceptional ones.

Learn more and apply to this contract here

The Contract: Fanuc CRX-20iA/L Aerospace Machine Tending

Here’s what we’re looking at:

System Overview: A Fanuc CRX-20iA/L collaborative robot automating a CNC machining cell. The robot picks raw stock pieces from a manually loaded drawer system, loads them into the CNC machine for precision machining operations, then removes finished aerospace parts and returns them to empty drawer positions. Clean workflow, tight tolerances, defense industry quality standards.

Scope of Work: Final debug and commissioning. The heavy lifting is done. Now we need someone who can fine-tune the system, validate cycle times, ensure repeatability, and get this cell into production mode.

Project Duration: One week onsite starting October 20, 2025, with possible follow-up installation support at the end user facility.

Location: Ontario, California. Southern California’s manufacturing corridor where aerospace, defense, and precision machining companies operate around the clock.

Rate: $77 per hour.

What You Need: Proven experience programming Fanuc collaborative robots, particularly the CRX series. Background in CNC machine tending applications. The ability to walk onto a shop floor, assess a system, troubleshoot independently, and commission it to production standards. Aerospace experience is valuable but not required if you understand what precision repeatability actually means.

This contract represents something larger than a week of programming work. It’s a snapshot of how American manufacturing maintains its competitive edge through smart automation, how defense contractors keep production lines running, and how independent automation professionals build careers that traditional employment could never offer.

Why Automate America Fills Critical Positions Like This Instantly

We have a network of over 40,000 automation professionals, controls engineers, robot programmers, and skilled trades experts across every industrial sector in North America. When an aerospace manufacturer needs a Fanuc programmer for a collaborative robot cell, they don’t post on generic job boards and wait three weeks for unqualified responses. They post on Automate America, and we connect them with vetted professionals who have actually commissioned CRX systems in production environments.

The difference is specificity. A general staffing agency doesn’t understand the difference between a Fanuc CRX-20iA/L and a CRX-10iA. They don’t know why collaborative robots require different safety protocols than industrial robots. They can’t distinguish between someone who has programmed robots in simulation versus someone who has debugged vision-guided pick-and-place systems on a factory floor at 2 AM when production is down.

Our network includes independent contractors who specialize in Fanuc collaborative robotics. Automation service companies that keep skilled programmers on staff specifically for short-term commissioning projects. System integrators with bench strength who contract their engineers through our platform when project timelines overlap. These aren’t people looking for jobs. These are professionals running businesses, and they choose projects based on technical interest, location, timing, and rate.

That’s why positions like this aerospace CNC machine tending project get filled immediately. The right programmer sees this posting, recognizes it as a clean commissioning job with a defined scope, calculates travel logistics, and applies within hours. No negotiating, no rate shopping, no uncertainty. The customer posts what they’re willing to pay. Professionals apply. We or the customer select the best fit. Everyone moves forward.

Fanuc CRX Collaborative Robots in Aerospace Manufacturing

Let’s talk about why this specific application matters. Aerospace manufacturing has always demanded precision that most industries never approach. When you’re machining components for military aircraft, defense systems, or satellite hardware, tolerances are measured in tenths of thousandths of inches. Surface finish requirements are brutal. Material traceability is mandatory. And production runs are typically low-volume, high-mix operations where setup time matters as much as cycle time.

Collaborative robots changed the economics of automating these environments. Traditional industrial robots require safety caging, extensive floor space, complex risk assessments, and significant capital investment. For a job shop running 50-piece lots of different aerospace parts every week, that math never worked. You couldn’t justify the cost and footprint.

The Fanuc CRX series solved that problem. These robots work alongside human operators without safety caging when properly risk-assessed and programmed. The CRX-20iA/L specifically offers a 20-kilogram payload with long reach, perfect for handling aerospace raw stock and machined components. The robot can pick parts from a drawer system that a human operator loads manually, eliminating the need for expensive automated part feeders. It loads the CNC, waits through the machining cycle, unloads the finished part, and returns it to the drawer. The operator inspects parts, performs secondary operations, and loads the next batch of raw stock.

This is smart automation. It doesn’t replace the skilled machinist. It eliminates the repetitive lifting, loading, and unloading that causes fatigue and ergonomic injuries. The machinist focuses on setup, tool changes, quality inspection, and process optimization. The robot handles the monotonous material handling. Production increases. Quality improves because the robot doesn’t get tired or distracted. The company can run lights-out shifts or extend production hours without adding headcount.

I’ve seen similar collaborative robot cells in aerospace machine shops from Seattle to Wichita to Connecticut. They all follow the same pattern. Start with one cell. Prove the ROI. Then expand to other machines. Within two years, the shop has six or eight cobots running CNC machine tending, and they’re wondering why they waited so long to automate.

The challenge is always the same. Getting the system installed and operational is the easy part. Fine-tuning the programming, optimizing cycle times, ensuring collision-free motion paths, integrating with CNC machine signals, and commissioning the cell to production standards requires a programmer who understands both the robot and the manufacturing process. That’s what this contract is about.

Skills and Training for Fanuc Collaborative Robot Programming

If you’re reading this and thinking about whether you have the right background for projects like this aerospace CNC machine tending cell, here’s what matters:

First, you need foundational knowledge of Fanuc robot programming. Understanding teach pendant operation, creating motion paths, setting I/O logic, working with coordinate systems, and programming pick-and-place routines. If you learned on older Fanuc industrial robots, that knowledge transfers directly to the CRX series. The programming language is consistent, though the CRX interface has some usability improvements.

Second, you need to understand collaborative robot safety standards. ISO/TS 15066 defines the requirements for collaborative robot applications. You need to know the four types of collaborative operations, understand speed and separation monitoring, know how to perform risk assessments, and program safety-rated monitored stop functions. This isn’t optional knowledge. It’s mandatory for commissioning any cobot system legally and safely.

Third, you need practical troubleshooting skills. When a robot won’t pick a part consistently, you need to diagnose whether it’s a gripper pressure issue, a vision system calibration problem, a part location variance, or a motion path timing error. When the CNC machine interface isn’t communicating properly with the robot, you need to trace signals, check I/O mapping, and validate handshake sequences. This comes from experience, not from reading manuals.

For professionals looking to develop or expand their Fanuc collaborative robot programming skills, I recommend starting with formal training:

Fanuc America Corporation offers comprehensive training courses specifically for the CRX series. Their Collaborative Robot Programming course covers everything from basic operation to advanced safety configuration. Check their training schedule at https://www.fanucamerica.com/services/training

RobotWorx provides hands-on Fanuc robot programming courses including collaborative robot applications and machine tending fundamentals. They offer both in-person and remote training options. Visit https://www.robots.com/education for course details and schedules.

The investment in formal training pays off immediately. A three-day programming course might cost $2,500, but it positions you for contracts paying $77 per hour or higher. One week-long project covers the training cost and puts you in front of customers who need ongoing automation support.

Beyond formal training, the best education comes from diversity of experience. Every industry uses collaborative robots differently. Aerospace focuses on precision and traceability. Automotive emphasizes cycle time and repeatability. Medical device manufacturing requires clean room protocols and validation documentation. Electronics assembly needs vision integration and micro-positioning. Working across these industries builds a depth of knowledge that no single employer could ever provide.

This is why independent contracting in automation creates better engineers than traditional employment. When you work for one company, you see one facility, one set of equipment, one approach to solving problems. You become an expert in that narrow domain. When you work as an independent contractor taking projects across industries and geographies, you see dozens of facilities, hundreds of different automation systems, and countless approaches to similar challenges. You learn what works universally and what only works in specific contexts. You build pattern recognition that makes you faster and more effective with every project.

The Strategic Value of Contract-to-Hire for Aerospace Manufacturers

Many manufacturers, particularly in aerospace and defense, still default to direct hire for automation engineering positions. They post a job requisition, wait weeks for applicants, conduct multiple interview rounds, make an offer, and hope the candidate accepts. Then they onboard the new hire, provide training, assign projects, and discover six months later whether they actually hired the right person.

This approach made sense in 1985. It makes no sense in 2025.

Contract-to-hire through platforms like Automate America eliminates the risk entirely. Instead of committing to a full-time salary, benefits, and overhead based on resume credentials and interview performance, you bring in a contractor for a defined project. You see their actual work quality, their communication style, their problem-solving approach, and their cultural fit. If they exceed expectations, you extend the contract or make a direct hire offer. If they’re merely adequate, you complete the project and move on. There’s no awkward termination, no unemployment claim, no wasted recruiting budget.

For this aerospace CNC machine tending project, imagine you bring in a Fanuc programmer for the one-week commissioning contract. They show up prepared, work efficiently, communicate clearly with your production team, complete the debug ahead of schedule, and leave detailed documentation. Three months later, you need someone to program two more collaborative robot cells. Who do you call? The contractor who already proved themselves in your facility.

This pattern repeats constantly. The best automation professionals on our platform work with the same customers repeatedly. They become trusted partners rather than interchangeable vendors. Manufacturers get consistent quality without the fixed overhead of full-time headcount. Contractors get steady work from customers who value their expertise.

The economics work for everyone. A manufacturer paying $77 per hour for a skilled Fanuc programmer gets someone who can work independently, complete projects on time, and deliver production-ready systems. They’re not paying benefits, not covering idle time between projects, not absorbing training costs. The fully burdened cost of a direct hire automation engineer typically exceeds $120 per hour when you include salary, benefits, payroll taxes, insurance, training, equipment, and overhead. Bringing in contractors at $77 per hour for defined projects is significantly more cost-effective.

For automation service companies, Automate America provides perfect workload balancing. When you’re busy with large integration projects, your bench engineers stay fully utilized on customer work. When project timelines create gaps, those same engineers can take short-term contracts through our platform. You’re not laying people off during slow periods or scrambling to find them work. You’re strategically deploying your workforce across both direct customers and platform contracts.

This is the future of automation workforce strategy. Flexible, skilled, project-based deployment of expertise exactly when and where it’s needed.

The Philosophy of Independence in Modern Manufacturing

There’s something profound happening in how technical professionals approach their careers, and this Fanuc CRX commissioning project embodies it perfectly. We’re moving from an industrial age model of permanent employment toward a renaissance of independent expertise.

For most of the 20th century, the goal was simple. Find a good company, get hired, work there for 30 years, retire with a pension. Security came from loyalty. Skill development came from doing the same type of work repeatedly. Career growth meant climbing a management ladder away from the technical work you actually enjoyed.

That world is gone. Companies restructure constantly. Pensions disappeared. Layoffs happen regardless of performance or loyalty. And the best engineers I know have zero interest in becoming managers who spend their days in meetings rather than solving technical problems.

Independent contracting offers something better. Agency. The ability to choose which projects you work on, where you work, who you work with, and what types of challenges you pursue. If you want to specialize in collaborative robotics, you take every cobot project available. If you want to work across industries, you deliberately choose diverse projects. If you prefer short intense commissioning work, you focus on one-week contracts. If you want longer engagements, you target multi-month installations.

This Fanuc CRX aerospace project is one week of work. For someone with the right skills, it’s also a paid opportunity to see how a defense contractor operates, learn their quality systems, understand their automation strategy, and potentially become their go-to programmer for future projects. It’s experience that compounds.

The traditional employment model extracts value from consistency. Do the same thing reliably, and you’re valuable. The independent contractor model creates value through diversity. Work on ten different collaborative robot systems across five industries, and you become exponentially more valuable than someone who programmed one system ten times.

This is why I believe independent contracting represents the pinnacle of professional development for automation engineers. Not because it’s easier. It’s harder. Not because it’s more secure. It requires self-discipline and financial planning. But because it transforms you from a specialist who knows one company’s approach into an expert who understands the full spectrum of how industries solve automation challenges.

For manufacturers, this same philosophy applies. Why commit to the fixed cost and inflexibility of direct hire employees when you can access world-class expertise on demand? Why assume the risk of hiring someone who looks perfect on paper but struggles in your environment? Why limit yourself to the talent pool within commuting distance of your facility when you can contract specialists from across the country?

The right approach is obvious. Use independent contractors and automation service companies for project-based work. Evaluate performance in real conditions. Make strategic direct hires only when you’ve proven the fit and have consistent long-term need. This isn’t about avoiding commitment. It’s about making smarter commitments based on demonstrated value rather than hopeful predictions.

Closing Thoughts

I hope this article gave you more than just information about a robot programming contract in California. If you’re an automation professional, I hope it reinforced why projects like this aerospace CNC machine tending commissioning represent exactly the kind of work that builds careers. If you’re a manufacturing leader or plant manager, I hope it clarified why platforms like Automate America deliver better outcomes than traditional hiring approaches.

The aerospace industry depends on precision, reliability, and continuous improvement. The same principles apply to workforce strategy. Bring in the right expertise at the right time. Value proven performance over credentials. Build relationships with professionals who consistently deliver results.

Whether you’re the Fanuc programmer who commissions this collaborative robot cell next week, or a manufacturer reading this and realizing you have similar automation needs, we’re here to connect you with solutions that work.

Thank you for reading. If you found value in this perspective on automation workforce strategy, career development, or manufacturing operations, I’m grateful for your time and attention.

Ready to join our network of 40,000+ automation professionals? Register here

Need to post automation contracts for your facility? Post work here

Perfect fit for this Fanuc CRX aerospace project? Apply now

Tony Wallace

Co-Founder, Automate America

586-770-8083

info@automateamerica.com